This is a down hole pump that is moving mineral oil.

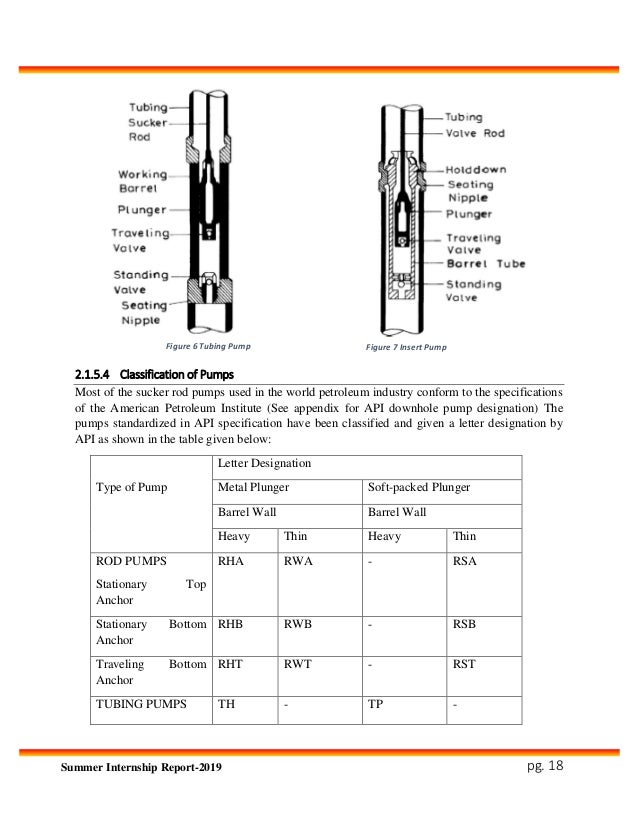

Insert pump oil field.

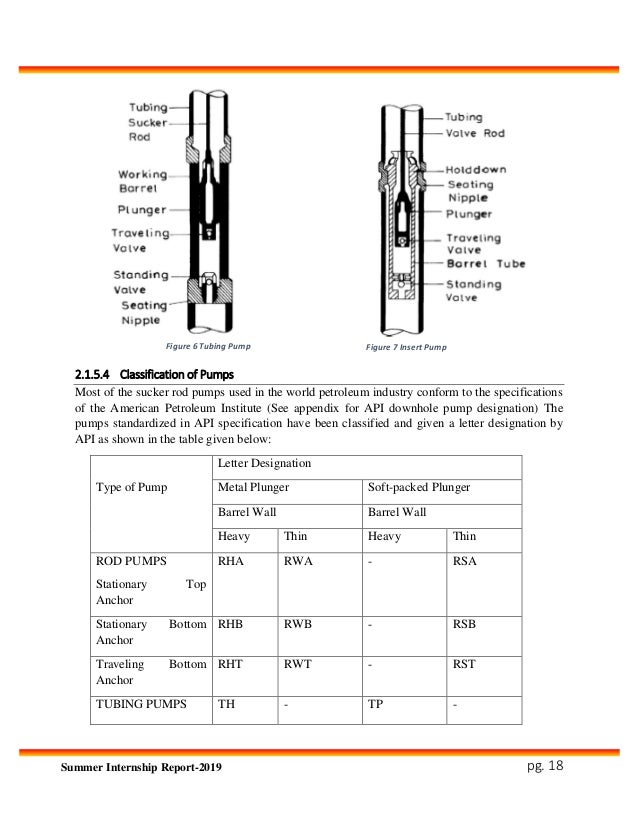

At the bottom of the tubing is the down hole pump.

When working in oil production the word insert specifies the pump has already been constructed as a complete and working pump and has been placed into the tubing string.

With repair shops strategically located in the most active areas we can service your downhole pump repair needs with experienced technicians able to provide root cause pump failure.

As a general rule the larger the pumpjack the deeper the reservoir.

When working in oil production the word insert specifies the pump has already been constructed as a complete and working pump and has been placed into the tubing string.

The pump should be smaller than the tubing pump and hence should consist of a less capacity of the given tubing size.

The visible parts of an oil field pump can range in size from small enough to fit in the bed of a pickup truck to structures the size of a house.

This pump has two ball check valves.

Thompson pump company s cbm pump is specially designed to eliminate gas lock and prevent the particles from packing and binding up a conventional pump.

Insert pumps can contain either a stationary.

This style of development was common in the oil booms of the early 20th century.

Notice the standing valves turbulence when you have your pound much lower in the stroke.

Our in house repair facility and extensive downhole pump parts inventory allows us to remedy the situation and get production back on line quickly and efficiently.

Hundreds of pumpjacks are visible in the full size view.

Downhole pump design and downhole pump repair are the backbone of knox oil field supply.

Examples of the 4 main pumps used in the majority of downhill pump designs trico industries inc insert pumps.

Insert pump is a pump which is inserted in the tubing and run like an assembled unit along with the sucker rods.

Electric submersible pump a pump located at the base of the well and powered by electricity from the surface.

The pump is removed from the tubing by pulling the sucker rod string.

In most oil field cases there are four common artificial lift types used.

One end of the beam is connected to a motor.

The typical pump comprises an a shaped frame topped by a long bar or beam.

This kind of pump is anchored in a mechanical or cup type seating nipple that runs as the part of the tubing string.

Besides the many styles of api downhole pumps there are also specialty pumps for severe applications such as sand gas interference and high viscosity oil.