The energy needed for mixing comes from a loss in pressure as fluids flow through the static mixer.

Inline static mixer design.

Static mixers are simple mixing devices effective in a variety of applications.

Static mixers are a low energy and efficient mixing device that can handle a wide range of applications.

This technique is essentially desirable wherever a continuous inexpensive and fast operation is required.

Kenics was the first static mixer produced and to this day is the leader in static mixer design and technology.

Learn about the working of laminar flow and turbulent flow.

Mixer significantly accelerates inline mixing or reaction.

Komax static mixers are applied to problems that range from the blending of heavy slurries and pastes to the mixing of low viscosity materials such as petroleum distillates and water additives.

Mixer size can vary from about 6 mm to 6 meters diameter.

For more than 40 years static mixers also known as motionless mixers have been successfully used as inline mixers for the mixing dispersing reaction and heating cooling of high and low viscosity liquids slurries gases and the multi phase contacting of gases solids and liquids.

Offering big advantages over motor driven mixers and competitive static mixers the komax design offers continuous processing of liquids gases and solids with predictable blending uniform temperature.

Principles of operation of static mixers.

One design of static mixer is the plate type mixer and another common device type consists of mixer elements contained in a cylindrical tube or squared housing.

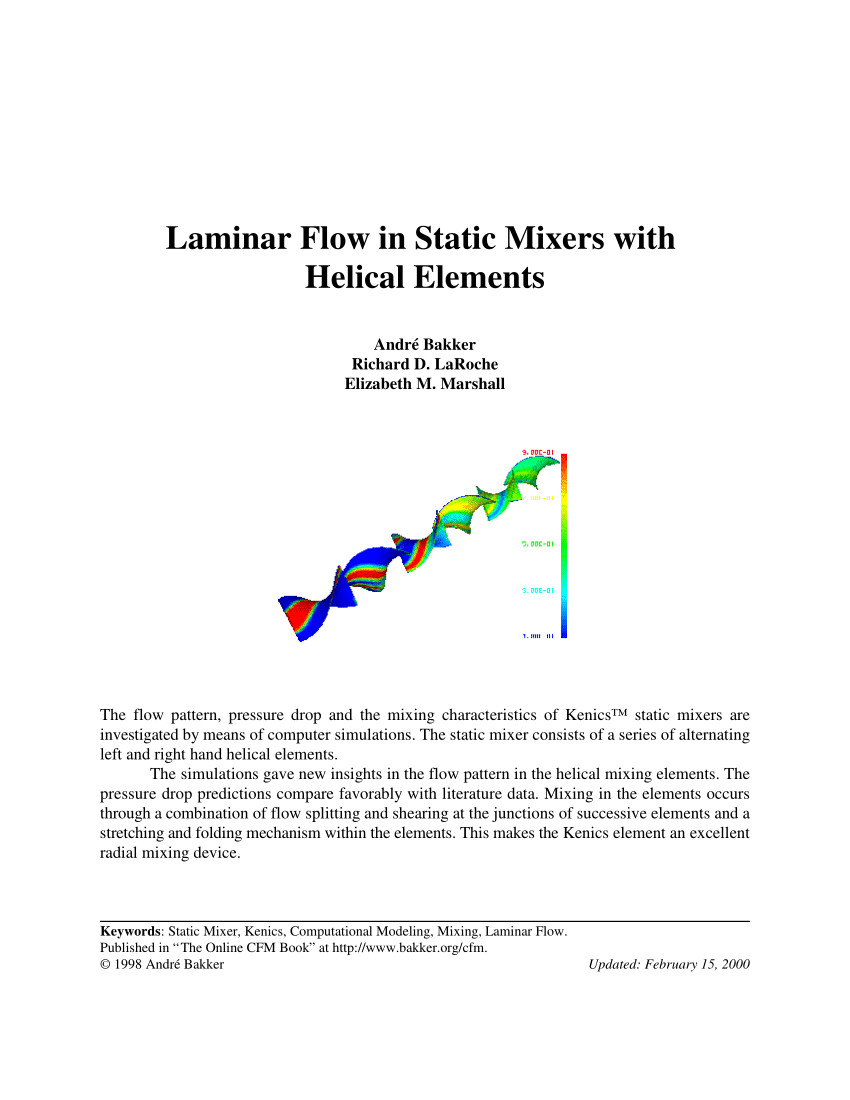

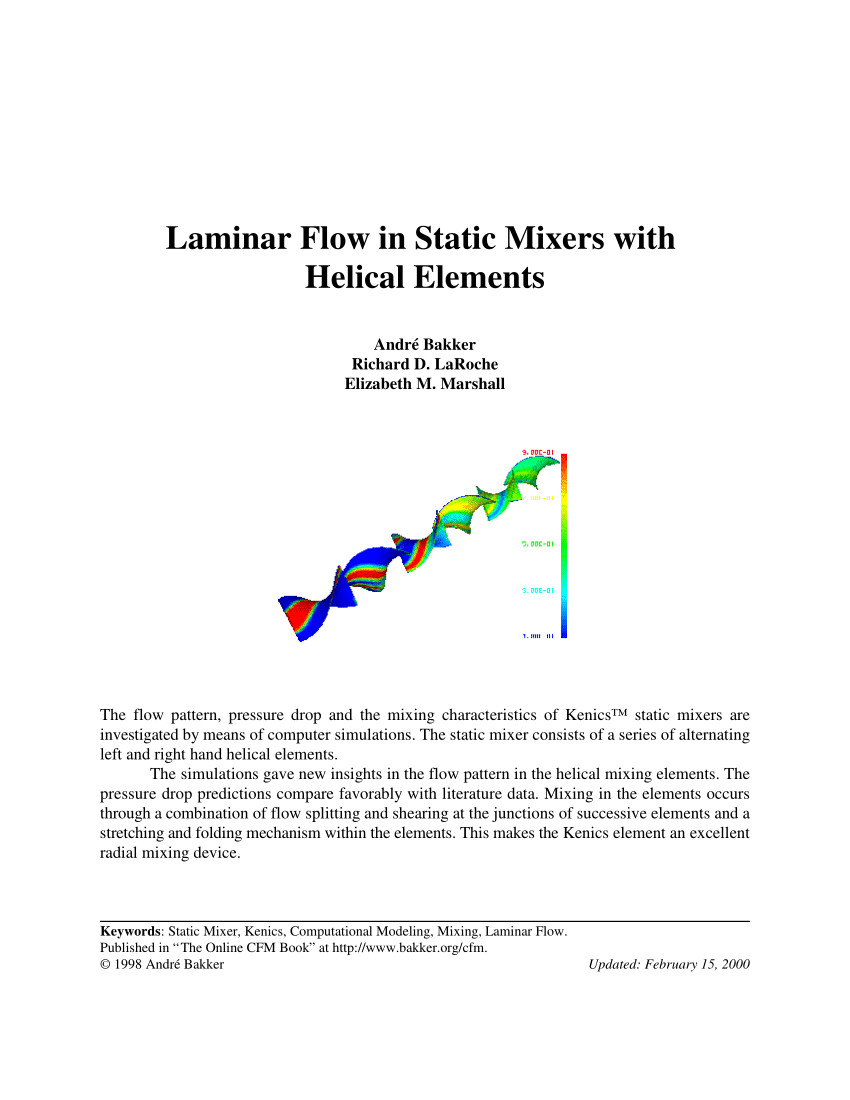

Kenics static mixer design.